The Cessna 172P Parts Manual is a comprehensive guide essential for maintenance and repairs. It provides detailed diagrams and part numbers, ensuring accurate ordering and compliance with safety standards.

1.1 Overview of the Cessna 172P Aircraft

The Cessna 172P is a highly reliable, single-engine aircraft renowned for its safety and performance. It is widely used for flight training, personal flying, and various aviation applications. Known for its durability and versatility, the 172P model features a Lycoming O-320 engine, delivering excellent fuel efficiency and climb performance. Its spacious cabin and comfortable design make it ideal for both instructors and passengers. With a strong track record of reliability, the Cessna 172P remains a popular choice for pilots of all experience levels. Its robust construction and consistent performance have solidified its reputation as one of the most trusted aircraft in general aviation.

1.2 Importance of the Parts Manual for Maintenance

The Cessna 172P Parts Manual is indispensable for maintaining aircraft airworthiness. It provides detailed part specifications, diagrams, and compatibility information, ensuring correct component identification. Technicians rely on it to source authentic parts, prevent mismatches, and adhere to safety standards. Regular updates keep the manual current with airworthiness directives, enhancing compliance. Proper documentation from the manual aids in tracking maintenance history, crucial for regulatory inspections. Its comprehensive nature minimizes errors, ensuring reliability and safety. Effective use of the parts manual is vital for extending the aircraft’s service life and maintaining operational integrity, making it a cornerstone of efficient maintenance practices for the Cessna 172P.

1.3 Historical Background of the Cessna 172P

The Cessna 172P, introduced in 1981, is a variant of the iconic Cessna 172, renowned for its reliability and ease of handling. It featured a 180-horsepower Lycoming O-360-A1G engine and a distinctive rear window, enhancing visibility. Produced until 1998, the 172P was widely used in flight training and personal aviation. Its durability and performance made it a favorite among pilots and instructors. Over the years, the 172P underwent improvements, including avionics upgrades and safety enhancements. Its legacy continues, with many still in service, a testament to Cessna’s commitment to producing robust and dependable aircraft. Understanding its history aids in appreciating the engineering and design that contributed to its enduring popularity in aviation.

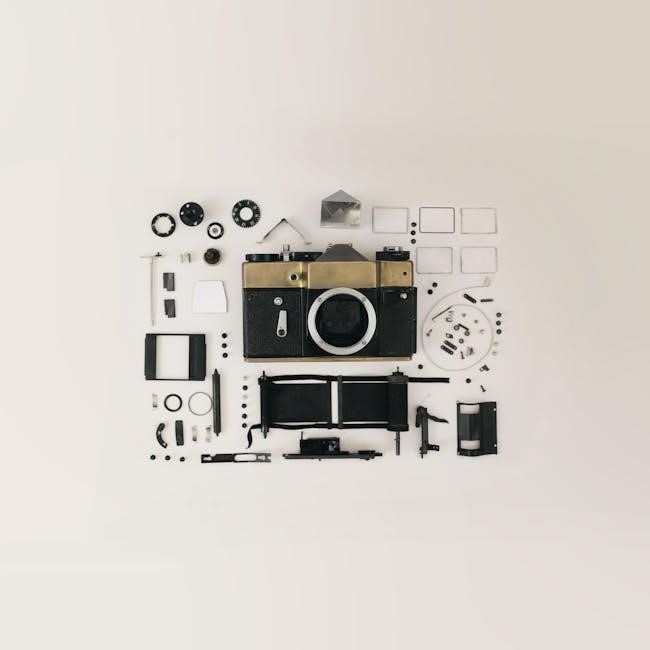

Structure of the Cessna 172P Parts Manual

The manual is divided into clear sections, including airframe, engine, and avionics. It features detailed diagrams, part numbers, and lists for easy identification and ordering of components.

2.1 Organization of the Manual

The Cessna 172P Parts Manual is meticulously organized to enhance accessibility. It begins with a table of contents, followed by detailed sections covering airframe, engine, avionics, and electrical systems. Each chapter is further divided into subsections, such as landing gear and fuel systems, ensuring quick reference. The manual includes high-quality diagrams and exploded views to simplify part identification. An alphabetical index and part number cross-reference are also provided, making it easier for users to locate specific components. This structured approach ensures that mechanics and owners can efficiently navigate and utilize the manual for maintenance, repairs, and upgrades.

2.2 Key Sections and Chapters

The Cessna 172P Parts Manual is divided into essential chapters for easy reference. Key sections include Airframe and Structural Components, detailing fuselage, wings, and control surfaces. The Engine and Propeller Systems chapter lists parts for the Lycoming O-320-H2AD engine and McCauley propeller. Fuel System Components cover tanks, pumps, and valves, while Electrical and Avionics Systems provide details for circuits and navigation equipment. The Landing Gear and Braking Systems section includes wheels, tires, and braking components. Additional chapters cover Tools and Equipment, Troubleshooting Common Issues, and Compliance with Airworthiness Directives. Each chapter is designed to help users locate parts efficiently, ensuring proper maintenance and adherence to safety standards.

2.3 How to Navigate the Manual Effectively

Navigating the Cessna 172P Parts Manual requires a systematic approach. Begin by reviewing the Table of Contents to identify relevant sections quickly. Use the Index to locate specific parts or systems by keyword. Cross-reference part numbers with detailed diagrams to ensure accuracy. For digital versions, utilize the search function to find components swiftly. Organize bookmarks or favorites for frequently accessed chapters. Pay attention to section headers and subheadings to narrow down your search. Understanding the manual’s structure, such as grouping by aircraft systems, enhances navigation efficiency. Familiarize yourself with the layout to streamline maintenance and repair processes, ensuring you find the information you need without delay.

Aircraft Systems and Components

The Cessna 172P Parts Manual details the aircraft’s systems, including airframe, engine, fuel, electrical, and landing gear components, providing a clear reference for maintenance and repairs.

3.1 Airframe and Structural Components

The Cessna 172P airframe is designed for durability and safety, featuring a robust structure to withstand various flight conditions. Key components include the fuselage, wings, and control surfaces, all constructed from high-strength aluminum alloys. The airframe is reinforced with riveted joints and internal bracing to ensure structural integrity. The wings are equipped with fuel tanks and support the flaps and ailerons, while the empennage houses the stabilizers and elevators. The landing gear, though fixed, is built to absorb impact during landings. Regular inspection of these components is critical to maintain airworthiness, as outlined in the parts manual. Proper maintenance ensures the structural integrity and longevity of the aircraft, making it a reliable choice for training and personal use.

3.2 Engine and Propeller Systems

The Cessna 172P is powered by a Lycoming O-320-E2D engine, producing 160 horsepower. This air-cooled, four-cylinder engine is reliable and efficient, with a reputation for durability. The engine is paired with a fixed-pitch McCauley propeller, designed to optimize performance at various altitudes. The parts manual provides detailed specifications for engine components, including cylinders, pistons, and valves, as well as propeller blades and hubs. Regular maintenance, such as oil changes and compression checks, is crucial to ensure engine longevity. The manual also outlines procedures for troubleshooting common issues like rough running or low power output. Adhering to these guidelines ensures the engine and propeller systems operate safely and efficiently, maintaining the aircraft’s performance and reliability.

3.3 Fuel System Components

The Cessna 172P fuel system consists of two wing-mounted fuel tanks, each with a capacity of 26.5 gallons, totaling 53 gallons. The system includes fuel pumps, selectors, filters, and distribution lines. The parts manual details components like the fuel selector valve, which directs fuel flow from either tank, and the electric fuel pump, ensuring consistent engine fuel supply. Regular inspection of fuel lines, fittings, and tanks is critical to prevent leaks and contamination. The manual also outlines procedures for draining fuel samples to check for water or debris. Proper maintenance of these components ensures reliable engine operation and safe flight performance, adhering to airworthiness standards.

3.4 Electrical and Avionics Systems

The Cessna 172P’s electrical system powers essential avionics, navigation, and communication equipment. Key components include the battery, voltage regulator, and circuit breakers. The avionics suite typically features a VHF communication radio, GPS, and transponder. The parts manual provides detailed schematics for troubleshooting electrical issues, such as faulty wiring or malfunctioning avionics units. Regular inspection of connectors and wiring is crucial to prevent failures. The manual also outlines procedures for upgrading or replacing avionics components, ensuring compliance with airworthiness standards. Proper maintenance of these systems is vital for safe and efficient flight operations, especially in instrument meteorological conditions. Adherence to the manual’s guidelines ensures reliable performance of all electrical and avionics systems.

3.5 Landing Gear and Braking Systems

The Cessna 172P’s landing gear and braking systems are designed for durability and reliability. The fixed tricycle landing gear features sturdy steel components, while the braking system includes disc brakes actuated by a master cylinder. The parts manual details replacement procedures for worn brake pads, wheels, and tires. Regular inspection of hydraulic lines and brake fluid levels is emphasized to prevent failures. The manual also covers lubrication schedules for moving parts to ensure smooth operation. Proper maintenance of these systems is critical for safe landings and ground operations. Adhering to the manual’s guidelines helps extend the service life of these components and ensures compliance with safety standards, reducing the risk of malfunctions during critical phases of flight.

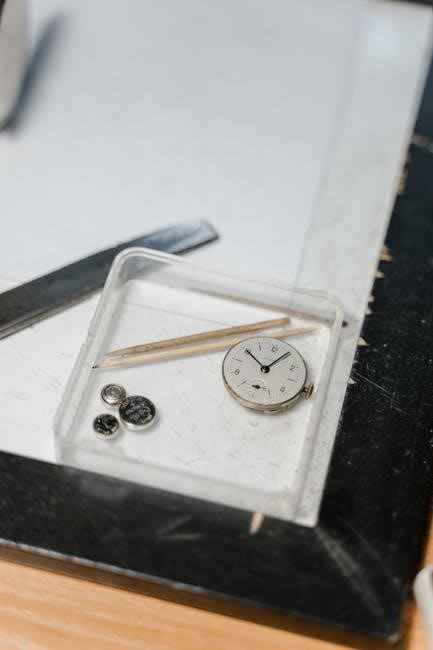

Tools and Equipment for Maintenance

Essential tools include wrenches, pliers, screwdrivers, and torque wrenches. Specialized equipment like rivet guns and hydraulic testers are also required. Safety gear such as gloves and goggles is crucial for protecting technicians during procedures, ensuring compliance with safety standards and efficient maintenance operations.

4.1 Essential Hand Tools for Cessna 172P Maintenance

Maintenance of the Cessna 172P requires a well-equipped toolkit. Essential hand tools include adjustable and fixed wrenches, pliers, screwdrivers, and torque wrenches. These tools are vital for tasks like tightening bolts, adjusting components, and securing fasteners. A socket set is also necessary for working with various bolt sizes. Additionally, a multimeter is indispensable for diagnosing electrical issues. It’s important to ensure all tools are of high quality and calibrated to specifications. Organizing tools in a structured manner can improve efficiency during maintenance. Always refer to the parts manual for specific tool recommendations. Proper tool usage helps prevent damage to aircraft components and ensures compliance with safety standards. Regular inspection of tools is advised to maintain reliability and performance.

4.2 Specialized Tools and Equipment

Beyond basic hand tools, the Cessna 172P requires specialized equipment for specific tasks. A rivet gun is essential for metalwork repairs, while a hydraulic pressure tester ensures proper braking system function. For avionics and electrical systems, a circuit tester and wiring diagram tools are indispensable. Fuel system maintenance demands a fuel pressure gauge and drain kit. Additionally, a propeller wrench and timing light are critical for engine-related tasks. Specialized fastener removal tools, like screw extractors, are also necessary. These tools are designed to handle unique aircraft requirements, ensuring precise and safe maintenance. Always use equipment recommended by the parts manual to avoid damage and maintain compliance with aviation standards. Proper use of specialized tools enhances efficiency and safety during repairs.

4.3 Safety Gear and Protective Equipment

Proper safety gear is crucial for maintaining the Cessna 172P. Essential items include safety glasses, gloves, and a fire extinguisher rated for aviation fires. Steel-toe boots and hearing protection are recommended for noisy environments. High-visibility clothing ensures visibility during inspections, while fall protection gear is vital for tasks requiring climbing. A spill kit is necessary for handling hazardous materials. Regularly inspect and maintain safety equipment to ensure reliability. Always follow aviation safety standards when working on the aircraft. Proper use of protective gear minimizes risks and ensures compliance with maintenance regulations; Never underestimate the importance of safety when performing repairs or inspections.

Troubleshooting Common Issues

Troubleshooting the Cessna 172P involves diagnosing issues like engine malfunctions or electrical glitches. Use the parts manual to identify components and apply corrective actions effectively.

5.1 Identifying Common Maintenance Problems

Identifying common maintenance issues in the Cessna 172P requires a thorough understanding of its systems. Frequent problems include engine performance inconsistencies, electrical system malfunctions, and wear on flight control surfaces. The parts manual provides detailed diagrams and part numbers, aiding in quick diagnosis. Corrosion in fuel tanks and landing gear components is another prevalent issue. Regular inspection of the airframe and propeller for cracks or damage is crucial. Additionally, avionics systems may experience glitches, requiring recalibration or replacement. By referencing the manual, technicians can pinpoint faulty components and ensure timely repairs, maintaining safety and airworthiness. Early detection of these issues prevents costly overhauls and extends the aircraft’s service life.

5.2 Diagnostic Techniques for Engine Malfunctions

Diagnosing engine malfunctions in the Cessna 172P involves systematic approaches to identify root causes. The parts manual provides essential guidance for troubleshooting. Begin with a visual inspection of the engine and related systems, checking for signs of wear, leaks, or damage. Utilize diagnostic tools to monitor engine performance parameters, such as oil pressure, temperature, and fuel flow. Compression tests and borescope inspections can reveal internal issues. Referencing the manual’s schematics helps pinpoint faulty components. Additionally, reviewing maintenance records and adhering to Airworthiness Directives ensures compliance and safety. By following these techniques, technicians can efficiently isolate and address engine problems, minimizing downtime and ensuring reliable operation.

5.3 Troubleshooting Electrical and Avionics Issues

Troubleshooting electrical and avionics issues in the Cessna 172P requires a systematic approach. Start by reviewing the parts manual for circuit diagrams and component locations. Check circuit breakers and fuses to ensure they are functioning properly. Use a multimeter to test voltage and continuity in suspect wiring. Common issues include faulty sensors, malfunctioning avionics units, or loose connections. Consult the manual for specific diagnostic procedures and replacement part numbers. Always refer to the latest Airworthiness Directives for compliance. Proper documentation of repairs is crucial for maintaining airworthiness records. By following these steps, technicians can efficiently identify and resolve electrical and avionics malfunctions, ensuring safe and reliable aircraft operation.

Compliance with Airworthiness Directives

Compliance with Airworthiness Directives ensures the Cessna 172P meets safety standards. Regular inspections, timely updates, and proper documentation are essential for maintaining airworthiness and operational safety.

6.1 Understanding Airworthiness Directives (ADs)

Airworthiness Directives (ADs) are official regulations issued by aviation authorities to address safety concerns or potential issues in aircraft design or operation. For the Cessna 172P, ADs often require specific inspections, modifications, or repairs to ensure compliance with safety standards. These directives are developed based on service history, incident reports, and manufacturer recommendations. Compliance with ADs is mandatory for maintaining the aircraft’s airworthiness certification and operational safety. The Cessna 172P Parts Manual plays a critical role in facilitating AD compliance by providing detailed instructions, part numbers, and specifications. Proper documentation of AD compliance is essential for legal and safety reasons, ensuring the aircraft remains safe for flight. Regular reviews of ADs are necessary to stay updated on new or revised requirements.

6.2 How to Ensure Compliance with ADs

Ensuring compliance with Airworthiness Directives (ADs) for the Cessna 172P involves a systematic approach. First, regularly review AD databases and subscribe to updates from aviation authorities. Identify applicable ADs for your aircraft’s specific model and serial number. Consult the Cessna 172P Parts Manual for detailed instructions and required parts. Schedule inspections and modifications as mandated, ensuring all work is performed by authorized personnel. Maintain thorough documentation of completed ADs, including dates, procedures, and personnel involved. Submit compliance records to the relevant aviation authority for verification. Finally, incorporate AD compliance into routine maintenance practices to uphold safety standards and prevent operational disruptions. Proactive compliance ensures the aircraft remains airworthy and safe for flight operations.

Maintenance Best Practices

Adhere to scheduled maintenance routines, referencing the Cessna 172P Parts Manual for precise procedures. Conduct thorough inspections, ensure proper tool usage, and maintain a clean, organized workspace to prevent errors.

7.1 Routine Inspection and Maintenance Tasks

Regular inspections are crucial for maintaining the Cessna 172P’s airworthiness. Start with a visual examination of the airframe, checking for signs of wear, corrosion, or damage. Ensure all control surfaces move freely and are properly secured. Inspect tires for wear and ensure proper inflation. The propeller and engine should be checked for nicks, cracks, or oil leaks. Review fuel system components for leaks or blockages. Perform routine lubrication of moving parts and replace filters as specified. Electrical systems should be tested for functionality, and avionics checked for accuracy. Always refer to the Cessna 172P Parts Manual for specific guidelines and part replacements.

7.2 Tips for Extending Aircraft Service Life

To extend the service life of your Cessna 172P, adhere to a rigorous maintenance schedule and follow the guidelines outlined in the parts manual. Regular cleaning and protective coatings can prevent corrosion, especially in coastal or high-humidity environments. Store the aircraft in a hangar when not in use to shield it from extreme weather conditions. Avoid aggressive flight maneuvers that may stress the airframe. Keep accurate maintenance records to track wear and tear. Use only approved replacement parts to ensure compatibility and durability. Properly secure control surfaces and protect sensitive avionics during storage. Address minor issues promptly to prevent them from becoming major repairs, ensuring your aircraft remains airworthy for years to come.

Purchasing and Sourcing Parts

Always source parts from authorized Cessna dealers to ensure authenticity and compliance. Verify part numbers and certifications to avoid counterfeit components, ensuring safety and reliability for your aircraft.

8.1 Authorized Dealers and Suppliers

When sourcing parts for your Cessna 172P, it is crucial to purchase from authorized dealers and suppliers. These dealers have direct access to genuine Cessna parts and ensure compliance with safety and airworthiness standards. Authorized suppliers provide detailed documentation, including certification and traceability, which are essential for maintaining your aircraft’s airworthiness. Additionally, they offer technical support and guidance, helping you identify the correct parts for your specific model. Always verify the dealer’s authorization status with Cessna Aircraft Company to avoid counterfeit or incompatible components. Using unauthorized suppliers can lead to safety risks and potential non-compliance with regulatory requirements. Prioritize reliability and safety by sourcing parts from trusted, official channels.

8.2 Tips for Buying Replacement Parts

When purchasing replacement parts for your Cessna 172P, always cross-reference part numbers with the official parts manual to ensure accuracy. Verify the compatibility of the part with your aircraft’s specific model and serial number. Check for any applicable airworthiness directives (ADs) that may require upgraded or modified components. Consider purchasing from authorized dealers to guarantee authenticity and compliance with safety standards. Additionally, look for parts with warranties or return policies to protect your investment. For critical systems, consult with a certified mechanic to confirm the suitability of the part. Finally, compare prices from multiple suppliers while ensuring the quality and reliability of the components. This approach ensures your aircraft remains airworthy and safe to operate.

Documentation and Record-Keeping

Accurate documentation ensures compliance with regulations and traceability of maintenance actions. Maintain detailed records of inspections, repairs, and part replacements for compliance and accountability purposes.

9.1 Importance of Maintenance Records

Maintenance records are critical for ensuring aircraft airworthiness and compliance with regulatory requirements. They provide a detailed history of all inspections, repairs, and part replacements, enabling traceability and accountability. Proper documentation helps identify recurring issues and ensures that all maintenance activities are conducted in accordance with approved procedures; Accurate records also facilitate compliance with airworthiness directives and maintenance schedules. Additionally, they serve as a communication tool between maintenance personnel and pilots, ensuring that all parties are aware of the aircraft’s status. Well-maintained records can also enhance the aircraft’s value by demonstrating its adherence to safety standards and proper upkeep. Regular audits and reviews of these records are essential to maintain operational integrity and safety.

9.2 How to Properly Document Repairs and Inspections

Proper documentation of repairs and inspections is vital for maintaining a clear and comprehensive maintenance history. All entries should be precise, including dates, parts replaced, and actions taken. Use standardized forms and adhere to the Cessna 172P Parts Manual guidelines. Include serial numbers and reference specific sections of the manual for clarity. Sign and date each entry to ensure accountability. Digital records are recommended for easy access and backup. Maintain a chronological order to track the aircraft’s condition over time. This systematic approach ensures compliance with airworthiness directives and provides a transparent record for future maintenance. Proper documentation also aids in identifying patterns that may indicate potential issues before they escalate. Consistency and thoroughness are key to effective record-keeping.

Glossary of Terms

- Airworthiness Directives (ADs): Mandatory regulations for ensuring aircraft safety and compliance.

- Service Bulletin: Manufacturer-recommended inspections or modifications.

- Horizon Line: A reference line in navigation instruments.

- Trim Tabs: Small surfaces controlling aircraft pitch and yaw.

10.1 Definitions of Key Aviation and Maintenance Terms

- Airworthiness Directives (ADs): Regulatory requirements for aircraft modifications to ensure safety and compliance with aviation standards.

- Service Bulletin: Manufacturer recommendations for inspections, repairs, or upgrades to maintain aircraft performance and safety.

- Trim Tabs: Small, adjustable surfaces on flight controls to balance aerodynamic forces and reduce pilot workload.

- Pitch: The upward or downward movement of the aircraft’s nose, controlled by elevators.

- Yaw: Rotation around the vertical axis, managed by the rudder.

- RPM: Revolutions per minute, measuring engine speed and performance efficiency.

Future Trends in Aircraft Maintenance

Emerging technologies like AI, predictive analytics, and digital manuals are transforming maintenance practices, enhancing efficiency and safety for aircraft like the Cessna 172P.

11.1 Advances in Technology for Maintenance

Advancements in technology are revolutionizing aircraft maintenance, particularly for the Cessna 172P. Digital manuals and AI-driven diagnostic tools now enable faster and more accurate troubleshooting. Predictive analytics helps identify potential issues before they occur, reducing downtime. Additionally, tools like Plane Maker allow for detailed customization and simulation, aiding in maintenance planning. Real-time data analysis from sensors and IoT devices further enhances proactive maintenance strategies. These innovations not only improve efficiency but also ensure compliance with safety standards. As technology evolves, maintaining the Cessna 172P will become safer, more efficient, and data-driven, benefiting both experienced mechanics and newer technicians alike.

11.2 Impact of Digital Manuals on Maintenance Processes

Digital manuals are transforming maintenance processes for the Cessna 172P. They offer instant access to updated information, reducing reliance on physical copies. Searchable content and hyperlinks enable quick navigation, streamlining tasks. Videos and interactive simulations enhance understanding of complex procedures. Real-time updates ensure compliance with the latest ADs and service bulletins. Digital tools also facilitate collaboration among technicians and reduce errors. Overall, digital manuals improve efficiency, accuracy, and accessibility, making maintenance safer and more effective. Their adoption is a significant step forward in modernizing aircraft upkeep, benefiting owners, mechanics, and pilots who rely on the Cessna 172P for its performance and reliability.